Know Your Countertops – An Educated Consumer

Stone of all types is in increasing demand for residential countertops in the U.S., because of its durability, beauty, and resale value. For many first-time stone purchasers, making a selection can be a daunting task. There are many basic stone types, and hundreds of colors within each stone type. Choosing a stone for your countertop application is like choosing a piece of artwork, in that it has a lot to do with personal taste, but there is also a technical aspect to what is right for you, and it is a lot easier to make your decision if you have knowledge about the product you’re about to purchase. Below is some basic information to help you make that decision.

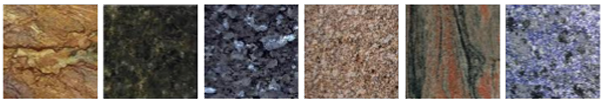

Stone Types

There are many stone types, each having its advantages and disadvantages in different countertop applications. The following are the common stone types used for countertops.

Granite:

This is the most common type of natural stone used for countertops in today’s market. Granite is a dense stone based on silica, quartz, mica and other minerals. It is a very hard and durable surface, offering high levels of resistance to abrasion, scratching, heat, and staining. You can prepare food directly on a granite countertop, if you don’t mind dulling your knives. With normal use and proper cleaning, stains and bacteria are not a concern. Granites properties make it an excellent choice for kitchen and other heavily used countertops.

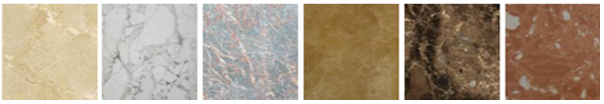

Marble:

Marble is a traditional stone used for centuries to evoke the feeling of opulence. Marble is a calcium carbonate based stone, so it is a softer and more porous stone, and therefore more susceptible to scratching and staining than granite. The calcium also reacts with acids, so it is susceptible to etching when exposed to acidic items like lemon juice, tomatoes, vinegar, etc. The use of inappropriate cleaning products may also cause etching. Whilst sealing a marble surface lessens its absorbency, it does not stop all absorbency, but merely slows the process, giving time to clean spills without ill effect. Due to these properties, Marble is less appropriate for use in kitchens, although in some parts of the world, a worn/stained top is view to have character. With proper care and maintenance, Marble is an excellent choice for vanities, credenzas, dressers, etc, that see less harsh use.

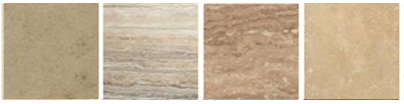

Limestone & Travertine:

Limestone and Travertine are softer, porous stones like Marble, and should be considered in the same way when selecting them for countertop applications.

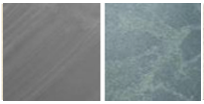

Soapstone:

Soapstone is highly compressed talc. Although dense and resistant to staining, soapstone countertops are softer than granite or marble, therefore prone to nicks and scratches.

Serpatinite:

This is one of the most misunderstood/misrepresented types of stone in the countertop industry. Many class it as a Marble, but based on its geological makeup, it is not. It consisting of magnesium, iron, silicate, chromium, cobalt and nickel (amongst other minerals). Serpentines can be slightly softer than granite, but a lot harder than marble, and some are equally as dense as granite, making it more than acceptable for high use areas like kitchens. The main drawback of this type of stone for countertop use is the fact it does not weather well if directly exposed to the elements for extended periods, so it is not appropriate for summer kitchens and BBQ’s that are not under cover.

Quartzite:

Quartzite is a natural stone that started out as sandstone, but due to tremendous heat and pressure crystallized into a harder, less porous material. There are many types of Quartzite, including Agate, Amethyst, Jasper, Onyx, Rose Quartz, Smoky Quartz, and Tiger-eye (to mention a few). These materials can exhibit translucent or opaque qualities, and some are considered semi-precious stones. Quartz is a constituent of Granite. Because of its dense crystalline structure, these materials have lower absorbency than Marbles, and tend to weather well.

Onyx:

Onyx is a type of quartzite. Its rich colors, patterns, and in many cases opaqueness and translucency, make it sought after for focal point applications like bars, vanities, dresses, etc. This translucency makes it ideal for back-lighting, to add to the “wow” factor of your countertop.

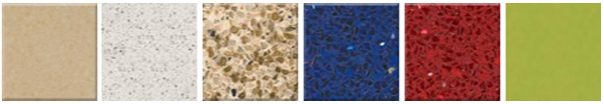

Quartz (Man-made):

Whilst there are several manufactures, there are two basic types of Man-made Quartz products. Those made of artificially grown quartz, and those using Natural Quartz. In both cases the quartz is broken into small pieces and mixed into a polymer resign, with coloring agents, and in some cases, post consumer material (recycled stone products). This mixture is then baked at high pressures and temperatures, to form a hard non-porous surface. This is idea material for all internal countertop surfaces, offering zero absorbency, and a consistent look. It is not recommended for external use.

Characteristics

Not only do the different stone types have different physical properties (as touched upon above), but they also have different visual properties. Some have a more consistent/reparative look to their patterning, where others will have strong veining and variegation. As a product of Mother-Nature, all natural stones will vary in appearance, texture, and character from slab to slab, and even within any given slab. Using consecutive slabs from the same bundle ensures the best color/pattern match possible across large areas. However variation may be unavoidably noticeable due to the given slabs character and the countertops shape. An experienced fabricator will be able to minimize this by strategic placement of the templates and seams, to give the best transition from one countertop panel to the next. With highly variegated materials, it is advisable for the home-owner and/or designer to participate in placement of the templates, so you can see what is and isn’t possible. Natural materials will also exhibit other characteristics like fissures, pits, and texture variations.

To quote the Marble Institute of America – Home Owners Guild to Natural Stone Countertop Installation (Page 8); “Fissures occur naturally in many stone types. A fissure is defined by the American Geological Institute as “an extensive crack, break, or fracture in the rock, which may contain mineral-bearing material.” The term “fissure” is used commercially in the stone industry to describe a visible separation along intercrystalline boundaries or the voids between mineral crystals. This separation may start and stop within the field of the stone or extend through an edge. A fissure differs from a crack in that it is a naturally occurring feature in the stone.”

Being a part of the stones character (as mother-nature made it), fissures cannot be considered defects or points of damage. Similarly, small pits and texture variations are naturally occurring and cannot be considered defects.

Design Considerations

Your cabinet layout, along with bumpouts, end panels, and trim pieces (filler strips, decorative columns, etc) will all govern the finished size of your countertops, so it is very important that these are all in place and secured before field measurements and/or templates are made. It should also be noted that once templates have been made, if anything is moved or changed, your countertops will not fit properly. Whilst the appliances need not be installed, the type/model #/specifications do need to be known, so the correct allowances can be made. Countertops typically overhang the front of the cabinet box by ~1 ½”-2”, to cover your door/draw fronts and fixtures, and allow room for the edge detail. Similarly they will overhang the end of a cabinet by 1”-1 ½”. So your (example) 36”x 24” cabinet is going to have a top in the vicinity of 38”x26” (~12.5% bigger area). This goes to highlight the importance of having the correct information when pricing out a countertop, and avoids later surprises.

If you have a raised upper counter or bar that cantilevers beyond the cabinets or supporting wall, you will need to consider the following limitations, before additional supports are required.

For a ¾” finished top, you should not exceed 6” overhang.

For a 1 ¼” finished top, you should not exceed 10” overhang.

For a 1 ½” finished top, you should not exceed 14” overhang. 1 ½” tops will have a plywood subtop bonded in place for additional strength at the area of overhang. Once you exceed these overhangs, the customer will be responsible for providing and installing additional supports (corbels or brackets). In no instance should the unsupported portion of the top be more than 1/3 of the total top width.

At the time of template, any sinks being used have to be available, so the correct size/shape cutout can be made. When selecting your sinks, keep in mind that Undermount Sinks have a lip below the countertop, which has to clear the front of the cabinet, and leave room in the back for your faucets and backsplash. This typically equates to 4” in the front, and 5” in the back. You also need to be cognizant of your cabinet width…is it wide enough for your sink?

Water weighs ~8 1/3 lbs per gallon. Some sinks will hold upward of 10 gallons of water, so that is ~83 lbs hanging from the bottom of your countertop. In some instances, more fragile material will require added support for the sink. If you plan on using a cast-iron sink, you will have to provide additional support in the cabinets for the sink, due to their heavy weight. Farmer sinks should be installed prior to template.

Natural stone is quarried in large blocks, then cut into slabs, and polished. The block size (and subsequent slab size) varies based on conditions at the quarry. More fragile materials are typically cut in smaller size slabs. Some material will have a fiberglass backing, to improve stability in shipping. Typical granite slabs range from 7’-9’ long, and 4½’-6’ wide. The dimensions of your chosen slabs should be considered when envisioning potential seam locations. To minimize the appearance of seams, it is often useful to place them at Sink or Cooktop cutouts, so there is only a short amount of seam visible. Experienced fabricators will be able to determine the best location for seams to optimize the pattern match across the seam, whilst minimizing the number of seams and material waste.

Granite and other stones are heavy (~10 ½ lbs/SF for ¾” thick granite). An 8 foot countertop will be in the vicinity of 200 lbs. In the case of larger tops (long continuous runs or Islands), consideration has to be give to the feasibility of a two-man crew maneuvering the sheer size and weight of your countertops from your driveway, thorough your house, and positioning them on your cabinets.

The most common natural stone surface finish is “Polished”. This gives a glossy surface that reflects light, and emphasizes the color and character of the stone. Some stone types do not lend themselves to polishing, and will be “Honed & Filled”. This gives a matte finish that does not reflect light (Travertine as an example). A “Honed” Granite surface will have a greyer look to it, and the natural color in the stone will not be as predominant. An enhancer can be used to bring out more of the natural color, but it will not be as vibrant as a polished surface. There are other textured surface finishes available, like “Brushed”, “Sandblasted”, and “Acid Washed”, but the look of these is very dependent on the particular stone, so you should discuss the suitability of using these finishes with your fabricator.

Scheduling to avoid conflicts with other trades is important. You cannot have countertops installed if you have freshly laid tile on the floor. You can’t have countertops installed if the house is being spray painted. You should not have other trades (plumbers, electricians) working in the same area where your countertops are being installed.

Care & Maintenance

The care required for natural stone surfaces varies slightly depending on the stone type, but if you follow the same Do’s & Don’t on all stone types, you are developing a good habit that will help maximize the beauty and longevity of your natural stone surfaces.

Do’s:

Blot up spills when they occur.

If a spilt product contains acids like tomato, citrus, vinegar, etc, they will degrade the Sealer, leading to absorption and potential staining and etching. Spills blotted up with paper towel within a few minutes will likely not cause any issues. If allowed to remain and absorb into the stone, not only will you have a stain, but acids will etch the surface. This is particularly important with calcious stones like Marble. Remember to blot the spill, as wiping will only spread it out over a bigger area.

Clean with mild soapy water.

Mild soapy water with a soft cloth or sponge is all that is needed to keep your countertops clean. Regular household cleaning products contain ammonia, which will degrade the Sealer and etch the surface of natural stone. Rinse the surface with fresh water after cleaning. This will help avoid the buildup of soap residue over time, which would give a dull appearance to the surface. Alternatively, you can use a natural stone cleaner specifically for the job. Triple D Marble & Granite offers a specially formulated stone cleaner for natural stone surfaces. Our “Stone Clean” product cleans and sanitizes the surface, as well as maintaining the condition of the Sealer, without leaving a residue. Enquire at our office (954-525-6135).

Rinse your countertop with fresh water.

Wiping your countertop with fresh water will dilute and rinse away any remaining spilt product. Rinsing after you have cleaned your countertop with mild soapy water will also help minimize soap residue buildup.

Reseal your countertops if needed.

With proper care your countertops should not need resealing for many years. The way to tell if resealing is required is to puddle a little fresh water on the surface. If it beads up like water on a waxed car, resealing is not required. But if it disappears into the surface leaving a dark spot, resealing is needed (the dark spot will go away as the stone dries). You can have your countertops resealed by a professional stone restoration and maintenance company, or you can buy a natural stone Sealer from your local big-box hardware store (follow the manufactures instructions).

Use coasters under bottles, cans, and glasses.

Bottles, cans, and glasses that contain acidic drinks may degrade the Sealer and etch the surface. This is a particularly important point in bathrooms.

Use a cutting board.

The use of a cutting board to protect your knives is a good habit to be in. Granite will rapidly dull the edge of your knife. A good cutting board is one that is softer than your knife (typically wood or plastic). The use of a cutting board also makes cleanup quicker and easier.

Don’ts:

Don’t use harsh cleaning products.

Using abrasive and or chemically harsh products can dull the finish, and damage the stone. Many household cleaning products contain ammonia, which will degrade the Sealer and etch the surface.

Don’t put hot pots directly on your countertop.

Whilst Granite is more than capable of withstanding the heat without damage, carbon and other grit trapped between a heavy pot and your countertop may put fine scratches and dull the surface over time. It is just a good habit to always use trivets on your countertop as a matter of course.

Don’t leave bathroom products on your countertop.

Use a tray under toiletry products. You know what toothpaste does to your teeth, so think of what it will do to your stone. Nail polish remover will strip away the Sealer, so leaving a bottle with a damp bottom sit on the countertop will leave a ring, which will get etched into the surface. An aerosol can in a humid bathroom environment will rust on the bottom, leaving a rust ring on your countertop. It is a good habit to use a tray under toiletry products, and avoid these potential issues.

Don’t sit or stand on your countertop.

Granite may be a strong material, but point loading from the weight of a human body will put stresses in the stone that may cause it to crack.

Treating Stains

Identifying what caused the stain is the first step to removing it, as different types of stains are treated in different ways. The prompt attention to a stain helps minimize the effect. The Marble Institute of America has a video called; “Care and Cleaning of Natural Stone in the Home.” This video touches on basic stone care, and the initial treatment of stains. If you’re uncomfortable with any of these procedures, you should contact a professional stone restoration and maintenance company.